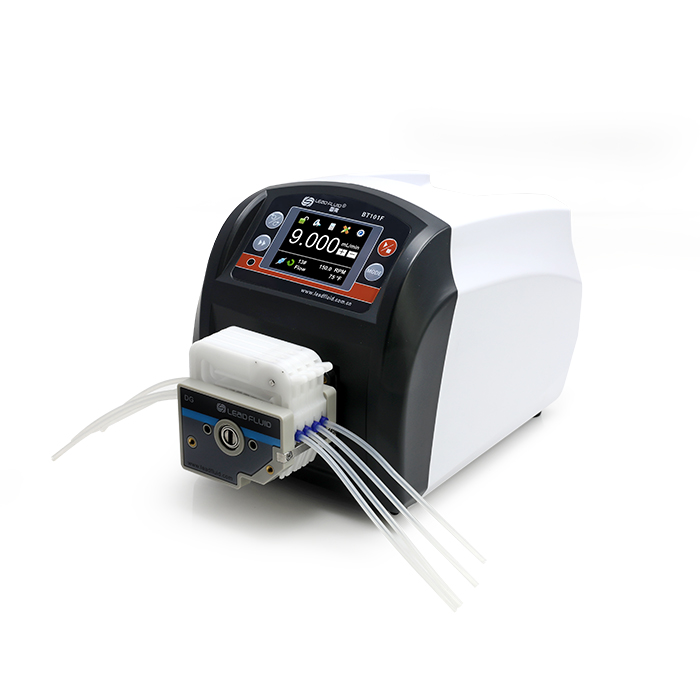

Flow rate pumps, including peristaltic pumps, are suitable for use in underwater instrumentation and sensors, provided they are appropriately designed and sealed to withstand the challenges of underwater environments.

Here are some factors to consider:

- Water Resistance: The pump must be water-resistant or waterproof to protect its internal components from water ingress. Sealed enclosures, waterproof connectors, and corrosion-resistant materials are essential for ensuring the pump’s integrity underwater.

- Material Selection: The materials used in the pump construction should be compatible with prolonged exposure to water, saltwater, and marine environments. Corrosion-resistant materials such as stainless steel, plastic, or marine-grade alloys are commonly used to ensure long-term durability.

- Sealing Mechanisms: Effective sealing mechanisms, such as O-rings, gaskets, or potting compounds, are necessary to prevent water from entering the pump housing and damaging internal components. Proper sealing ensures the pump remains watertight even under high-pressure conditions encountered in deepwater applications.

- Pressure Handling: The pump should be capable of operating under the hydrostatic pressure encountered at various depths underwater. Robust construction and reinforced components may be required to withstand the pressure exerted by the surrounding water column.

- Corrosion Resistance: Components exposed to seawater or saltwater environments must be corrosion-resistant to prevent degradation over time. Special coatings, platings, or materials with inherent corrosion resistance can protect against rust and deterioration.

- Temperature Tolerance: The pump should be capable of operating within the temperature range expected in the underwater environment. Thermal insulation or cooling mechanisms may be necessary to maintain optimal performance and prevent overheating or freezing of components.

- Low Noise Operation: In some underwater applications, such as marine research or acoustic sensing, low noise operation is critical to minimize interference with sensitive measurements or observations. Quiet pump operation reduces acoustic pollution and ensures accurate data collection.

- Variable Flow Control: Depending on the application, the pump may need to offer variable flow control to adjust fluid flow rates based on changing environmental conditions or experimental requirements. Adjustable speed settings or flow rate control mechanisms enable flexibility in pump operation.

- Integration with Sensors: The pump should be compatible with sensors and instrumentation commonly used in underwater applications. Compatibility with data acquisition systems, communication protocols, and power requirements facilitates seamless integration into underwater sensor networks or monitoring platforms.

- Energy Efficiency: Energy-efficient pump designs help conserve battery power in underwater systems, prolonging operational autonomy and reducing the need for frequent maintenance or battery replacement.

By addressing these considerations, flow rate pumps can be effectively deployed in underwater instrumentation and sensor applications, providing reliable fluid handling capabilities for a wide range of marine research, monitoring, exploration, and industrial tasks.