This comprehensive guide explores what flexible grooved couplings are, their key features, and how they enhance piping connections. Explore their applications in various industries.

Flexible grooved couplings are essential components in modern piping systems, offering numerous benefits and advantages.

In this article, we will delve into the world of flexible grooved couplings, exploring their features, applications, and the advantages they bring to various industries.

Whether you’re involved in plumbing, HVAC, or fire protection projects, understanding the capabilities and benefits of flexible grooved couplings is crucial for optimizing system performance and efficiency.

I. What Are Flexible Grooved Couplings?

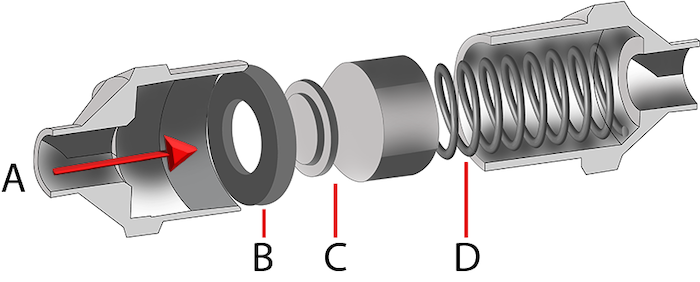

Flexible grooved couplings are mechanical connectors used to join and secure pipes in a wide range of applications.

These couplings consist of two housings with grooves that match the pipe’s grooved ends. They also incorporate a gasket that provides a reliable seal and allows for movement and flexibility.

Designed for easy installation, flexible grooved couplings offer a time-saving and cost-effective method for connecting pipes.

II. Key Features and Benefits of Flexible Grooved Couplings

- Easy Installation:

One of the primary advantages of flexible grooved couplings is their ease of installation. With their simple design and no need for specialized tools or welding, these couplings significantly reduce installation time and labor costs. - Flexibility and Movement:

Flexible grooved couplings allow for controlled movement within the system, accommodating thermal expansion, vibration, and deflection. This flexibility helps prevent stress on the pipes and reduces the risk of leaks or failures. - Durability and Reliability:

These couplings are constructed from high-quality materials, such as ductile iron or stainless steel, ensuring durability and long-term performance.

They are resistant to corrosion, providing a reliable and maintenance-free solution for piping connections.

III. Applications of Flexible Grooved Couplings

Flexible grooved couplings find extensive use in various industries due to their versatility and reliability. Some notable applications include:

- Plumbing and Water Distribution:

In plumbing systems, flexible grooved couplings are used for connecting water supply lines, drainage systems, and wastewater pipes.

Their ease of installation and flexibility make them ideal for both residential and commercial plumbing projects. - HVAC Systems:

Flexible grooved couplings play a crucial role in HVAC systems, connecting pipes for heating, ventilation, and air conditioning.

These couplings accommodate thermal expansion and contraction, ensuring efficient and reliable performance of the HVAC system. - Fire Protection Systems:

Flexible grooved couplings are widely employed in fire protection systems, connecting pipes that carry water or other fire suppression agents.

Their durability, easy installation, and flexibility make them essential for ensuring the effectiveness and safety of fire protection networks.

IV. Conclusion

Flexible grooved couplings offer numerous advantages in piping systems across different industries. Their ease of installation, flexibility, and durability make them a preferred choice for professionals seeking efficient and reliable pipe connections.

Whether in plumbing, HVAC, or fire protection projects, these innovative couplings enhance system performance, reduce maintenance costs, and provide long-term reliability.

By incorporating flexible grooved couplings into your piping systems, you can ensure optimal performance, improved flexibility, and peace of mind.