In this article, we delve into the world of stainless steel grooved fittings and explore the possibility of grooving stainless steel pipe. We discuss the benefits and challenges of grooving stainless steel and provide examples of stainless steel grooved fittings in various industries.

Can Stainless Steel Pipe be Grooved?

Stainless steel is a popular material in various industries due to its corrosion-resistant properties and durability. However, can stainless steel pipe be grooved? In this article, we will explore the possibilities and limitations of grooving stainless steel pipe.

Stainless Steel Grooved Fittings

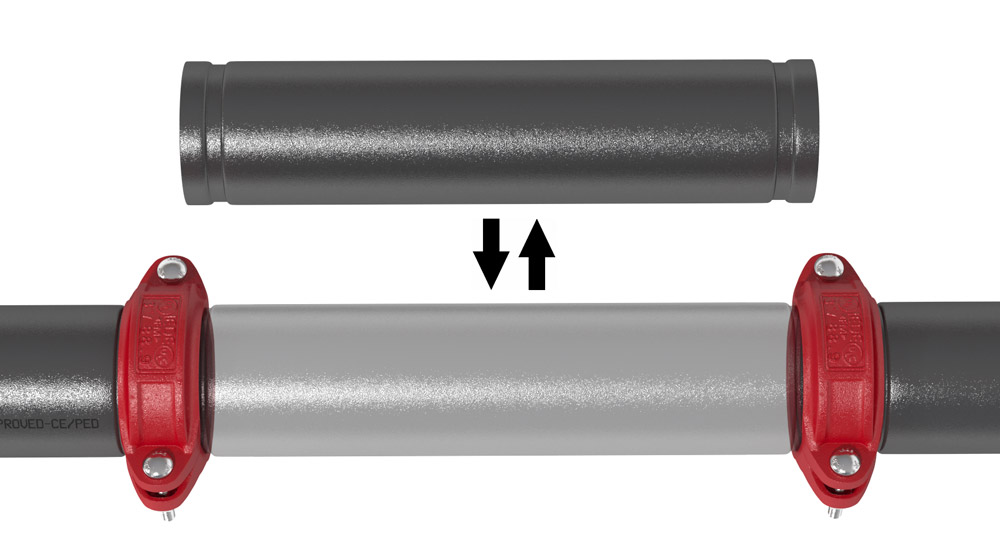

Stainless steel grooved fittings are a type of fitting that is designed to connect stainless steel pipes and tubes. These fittings are grooved to provide a secure connection and can be used in various industries, including food and beverage, pharmaceutical, and chemical processing.

Benefits of Grooving Stainless Steel Pipe

Grooving stainless steel pipe offers several benefits, including improved flow characteristics, reduced pressure drop, and increased safety. Grooved fittings also provide a secure connection and can withstand high pressures and temperatures.

Challenges of Grooving Stainless Steel Pipe

Despite the benefits of grooving stainless steel pipe, there are also some challenges to consider. One of the main challenges is the difficulty in manufacturing grooved fittings, particularly for large diameter pipes. Additionally, the grooves can be prone to damage during handling and installation.

Examples of Stainless Steel Grooved Fittings

Stainless steel grooved fittings are used in a variety of industries, including:

- Food and beverage: Stainless steel grooved fittings are used in food processing and packaging, providing a sanitary and durable connection.

- Pharmaceutical: Grooved fittings are used in the pharmaceutical industry for the transportation of fluids and powders.

- Chemical processing: Stainless steel grooved fittings are used in chemical processing plants for the transportation of corrosive liquids and gases.

Conclusion:

In conclusion, stainless steel grooved fittings are a popular choice in various industries due to their durability and corrosion-resistant properties. While grooving stainless steel pipe can be challenging, the benefits of improved flow characteristics and increased safety make it a viable option for many applications.

By understanding the benefits and challenges of grooving stainless steel pipe, engineers and manufacturers can select the appropriate fittings for their specific needs.