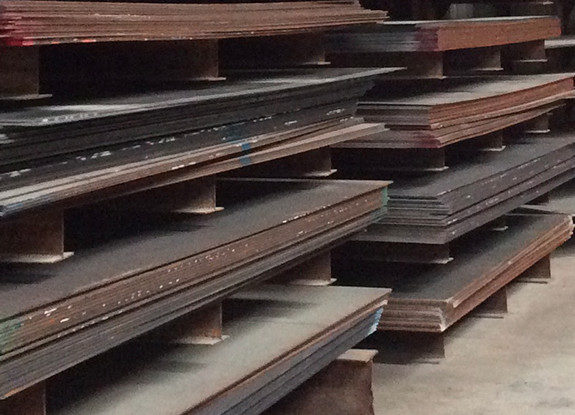

3×3 square tubing is a type of steel tubing that is popular in a variety of industries due to its strength and versatility. Its square shape makes it ideal for structural applications, such as building frames and supports.

Introduction:

3×3 square tubing is a versatile and durable material that has a variety of applications in different industries. It’s strength and square shape make it ideal for structural applications, such as building frames and supports. In this article, we’ll take a closer look at the features and benefits of 3×3 square tubing, as well as its various applications.

.jpg)

Features and Benefits of 3×3 Square Tubing

3×3 square tubing is a type of steel tubing that is characterized by its square shape and strength. It is often used in structural applications due to its ability to support heavy loads. Additionally, the square shape of the tubing makes it ideal for welding and joining, making it easy to connect with other materials.

Applications of 3×3 Square Tubing in Construction

3×3 square tubing is commonly used in the construction industry for a variety of applications. It can be used to create frames and supports for buildings, bridges, and other structures. Additionally, it can be used to create fencing and barriers, as well as for decorative purposes.

Applications of 3×3 Square Tubing in Manufacturing

In addition to construction, 3×3 square tubing is also commonly used in manufacturing applications. It can be used to create frames and supports for machinery and equipment, as well as for creating conveyor systems and other material handling equipment.

.jpg)

Applications of 3×3 Square Tubing in Transportation

3×3 square tubing is also used in the transportation industry for a variety of applications. It can be used to create frames and supports for trucks and trailers, as well as for creating racks and storage systems for cargo.

Conclusion:

In conclusion, 3×3 square tubing is a versatile and durable material that has a wide range of applications in different industries. It’s strength and square shape make it ideal for structural applications, such as building frames and supports. Additionally, it can be used in manufacturing and transportation industries for creating machinery, equipment, and storage systems. By using 3×3 square tubing, you can ensure that your project is strong, durable, and able to withstand heavy loads.

.jpeg)

Overall, the versatility and strength of 3×3 square tubing make it an ideal material for a variety of applications across different industries. Whether you’re working in construction, manufacturing, or transportation, 3×3 square tubing can provide the support and durability you need for your project.

.jpeg)

-1024x786.jpg)

-1024x683.jpg)

.jpg)

-1024x575.jpg)

-1024x768.jpg)