Firefighting systems are essential for ensuring the safety of people and property in various settings. This article will explore the importance of grooved fittings for firefighting systems and provide a comprehensive guide.

What are Grooved Fittings?

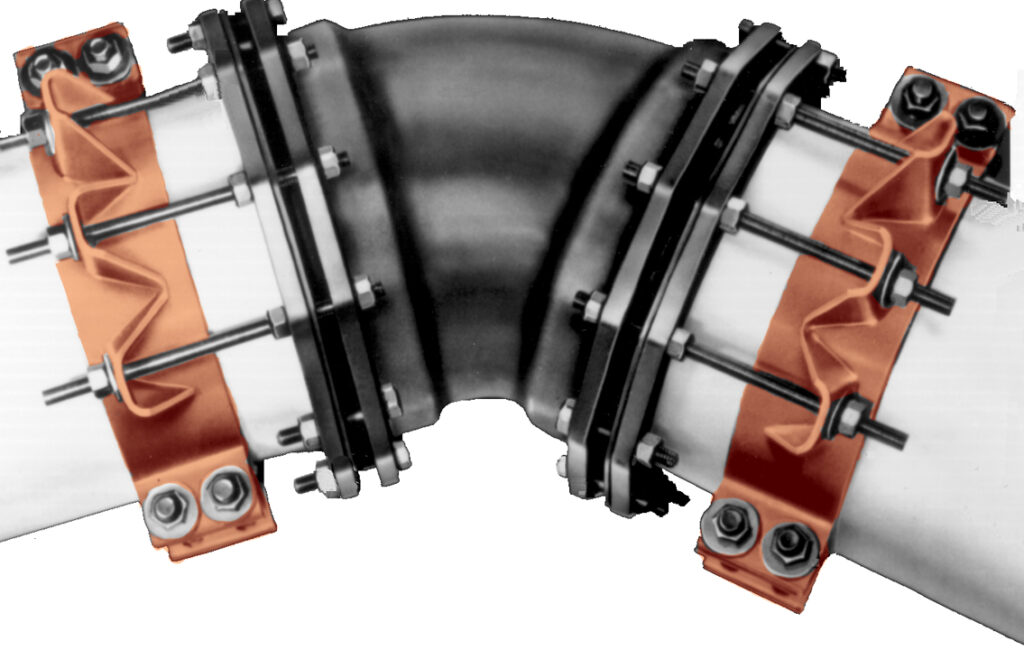

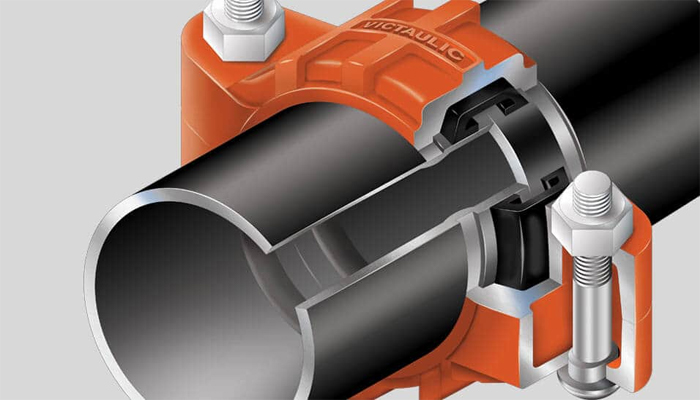

Grooved fittings are used to connect pipes in a fire fighting system. They are designed with a groove or channel that runs along the length of the fitting, which receives the pipe and provides a secure connection.

The groove is typically surrounded by a raised lip or bead that helps to maintain the connection and prevent leakage. Grooved fittings are available in various sizes and materials, including steel, brass, and plastic.

Benefits of Grooved Fittings

Grooved fittings offer several benefits for fire fighting systems, including:

- Security: Grooved fittings provide a secure connection between pipes, ensuring that the system remains intact and functional during emergencies.

- Reliability: The groove and raised lip design of grooved fittings ensure that the connection remains stable and reliable, even in high-pressure situations.

- Easy Installation: Grooved fittings are easy to install and require minimal tools, making them a convenient option for firefighting system installations.

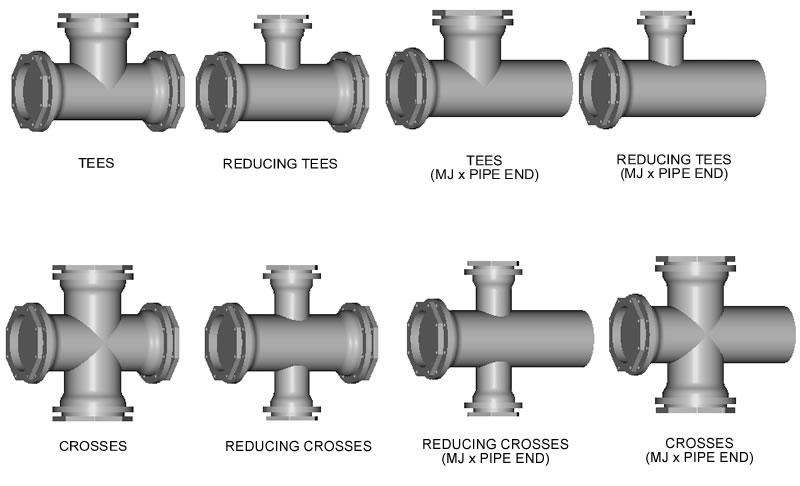

- Versatility: Grooved fittings are available in various materials and sizes, making them suitable for a wide range of firefighting applications.

Applications of Grooved Fittings

Grooved fittings are commonly used in various firefighting applications, including:

Sprinkler Systems: Grooved fittings are used to connect pipes in sprinkler systems, ensuring that water is distributed evenly and efficiently.

Fire Hydrants: Grooved fittings connect fire hydrants to the main water supply, providing a reliable source of water for firefighting.

Fire Alarm Systems: Grooved fittings connect pipes in fire alarm systems, ensuring that the system remains functional and alerts authorities in an emergency.

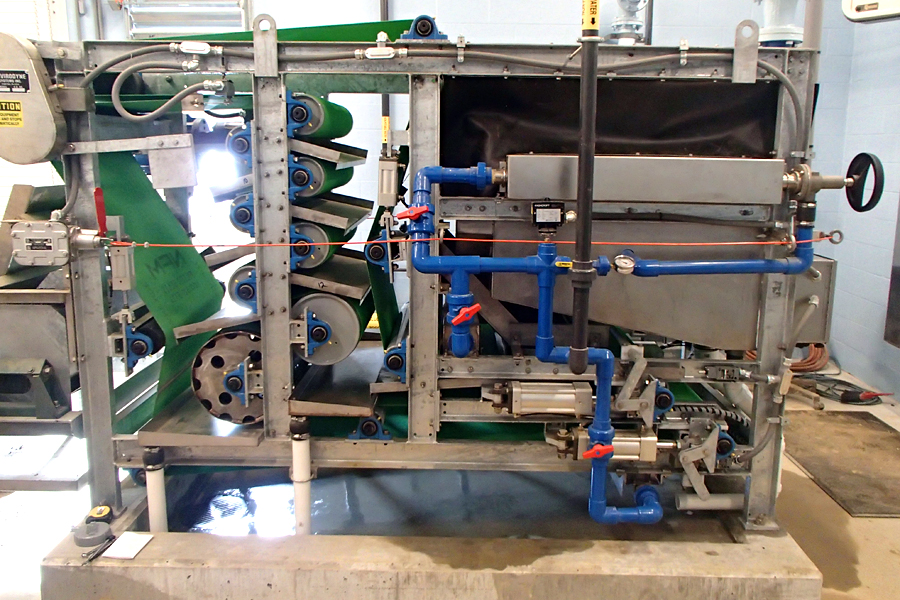

Fire Suppression Systems: Grooved fittings are used to connect pipes in fire suppression systems, providing a reliable source of water or other fire-fighting agents.

Choosing the Right Grooved Fittings

When choosing grooved fittings for firefighting systems, it is essential to consider the following factors:

- Material: Grooved fittings are available in various materials, including steel, brass, and plastic. Steel and brass fittings are more durable and suitable for high-pressure applications, while plastic fittings are lighter and more affordable.

- Size: Grooved fittings are available in various sizes, ranging from 1/2 inch to 4 inches. The size of the fitting should match the size of the pipe it will be connecting.

- Pressure Rating: Grooved fittings have different pressure ratings, ranging from 150 psi to 1000 psi. The pressure rating should match the pressure requirements of the firefighting system.

- Compatibility: Grooved fittings should be compatible with the type of pipe used in the firefighting system.

Conclusion

Grooved fittings are a critical component of firefighting systems, providing a secure and reliable connection between pipes. By understanding the benefits, applications, and factors to consider when choosing grooved fittings, you can ensure that your fire fighting system is effective and efficient.

At JIANZHI manufacturer, we offer a wide range of grooved fittings for fire fighting systems, suitable for various applications and requirements. Contact us today to learn more about our products and services.