Mechanical pipe fittings are an essential component in industrial plumbing systems. They are used to connect pipes and tubes in various configurations, allowing for the efficient transportation of fluids, gases, and slurries.

With so many different types of fittings available, it can be challenging to determine which ones are best suited for a particular application.

In this article, we will explore the different types of mechanical pipe fittings, their uses, and the factors to consider when selecting them.

Types of Mechanical Pipe Fittings

Mechanical pipe fittings come in a variety of shapes, sizes, and materials. Some of the most common types include:

1. Elbows

Elbows are used to change the direction of a pipe or tube. They are available in various angles, such as 90-degree elbows, 45-degree elbows, and 180-degree elbows.

2. Tees

Tee fittings are used to connect two pipes or tubes at a 90-degree angle. They have a T-shaped design and are available in various sizes.

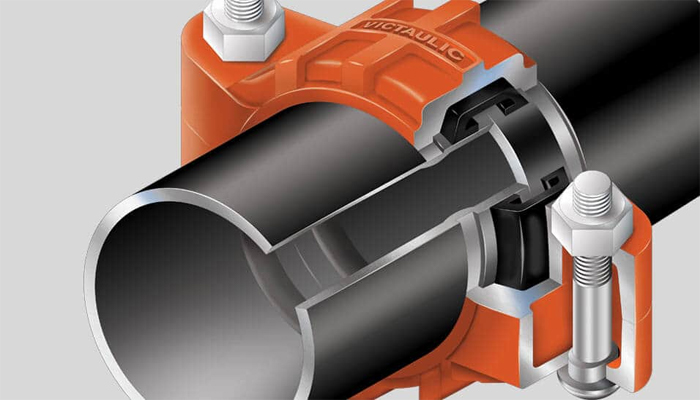

3. Couplings

Couplings are used to connect two pipes or tubes end-to-end. They are available in various materials, such as steel, brass, and stainless steel.

4. Unions

Unions are used to connect two pipes or tubes end-to-end, allowing for easy disconnection and reconnection. They are commonly used in industrial applications.

5. Valves

Valves are used to control the flow of fluids, gases, and slurries. They come in various types, such as ball valves, gate valves, and butterfly valves.

Factors to Consider When Selecting Mechanical Pipe Fittings

When selecting mechanical pipe fittings, there are several factors to consider. Here are some of the most important ones:

1. Material

The material of the fitting should match the material of the pipe or tube it will be connected to. Common materials include steel, brass, stainless steel, and PVC.

2. Size

The size of the fitting should match the size of the pipe or tube it will be connected to. The fitting should be able to slide onto the pipe or tube easily and securely.

3. Pressure rating

The pressure rating of the fitting should match the pressure rating of the pipe or tube it will be connected to. The fitting should be able to withstand the maximum pressure of the system.

4. Temperature rating

The temperature rating of the fitting should match the temperature rating of the pipe or tube it will be connected to. The fitting should be able to withstand the maximum temperature of the system.

5. Compatibility

The fitting should be compatible with the type of fluid, gas, or slurry being transported. For example, a fitting used in a chemical plant should be able to withstand the corrosive properties of the chemicals.

Conclusion

Mechanical pipe fittings are a critical component in industrial plumbing systems. There are various types of fittings available, each with its unique characteristics and uses.

When selecting mechanical pipe fittings, it is important to consider factors such as material, size, pressure rating, temperature rating, and compatibility.

By understanding the different types of fittings and their uses, industrial plumbing systems can be designed and installed efficiently and effectively.

FAQs

- What are mechanical pipe fittings used for?

Mechanical pipe fittings are used to connect pipes and tubes in various configurations, allowing for the efficient transportation of fluids, gases, and slurries. - What are the different types of mechanical pipe fittings?

The different types of mechanical pipe fittings include elbows, tees, couplings, unions, and valves. - What factors should be considered when selecting mechanical pipe fittings?

Factors to consider when selecting mechanical pipe fittings include material, size, pressure rating, temperature rating, and compatibility. - What is the maximum pressure rating of mechanical pipe fittings?

The maximum pressure rating of mechanical pipe