Tungsten Inert Gas (TIG) welding is a popular welding process used in various industries, including aerospace, automotive, and medical. TIG welding allows for precise and clean welds, making it an ideal choice for intricate work. In this article, we will explore the TIG welding process, its advantages and disadvantages, and its applications.

Introduction

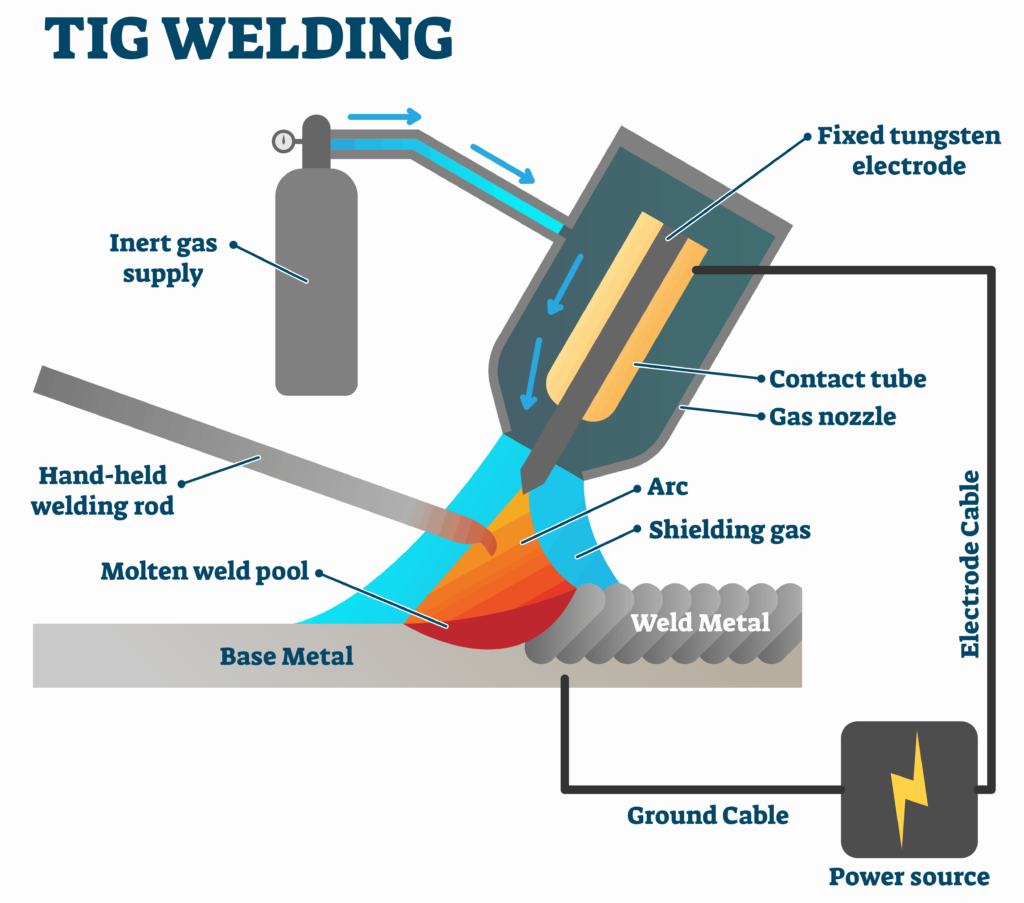

TIG welding is a process that uses a tungsten electrode to heat the metal and create a weld. The process also uses an inert gas, typically argon, to protect the weld from contamination.

TIG Welding Process

The TIG welding process involves several steps, including:

- Preparation: This includes cleaning the surfaces to be welded and ensuring proper fit-up.

- Tack welding: This involves temporarily holding the sections of metal together with small welds to ensure they remain in place during the welding process.

- Welding: This involves using the tungsten electrode to heat the metal and create a weld. The inert gas is used to protect the weld from contamination.

- Finishing: This involves cleaning up the weld and removing any excess material.

Advantages and Disadvantages

TIG welding offers several advantages, including:

- Precision: TIG welding allows for precise control of the heat and the weld.

- Cleanliness: TIG welding produces clean and aesthetically pleasing welds.

- Versatility: TIG welding can be used on a wide range of metals, including aluminum, stainless steel, and copper.

However, TIG welding also has some disadvantages, including:

- Time-consuming: TIG welding is a slow process compared to other welding methods.

- Skill level: TIG welding requires a high level of skill and experience.

Applications

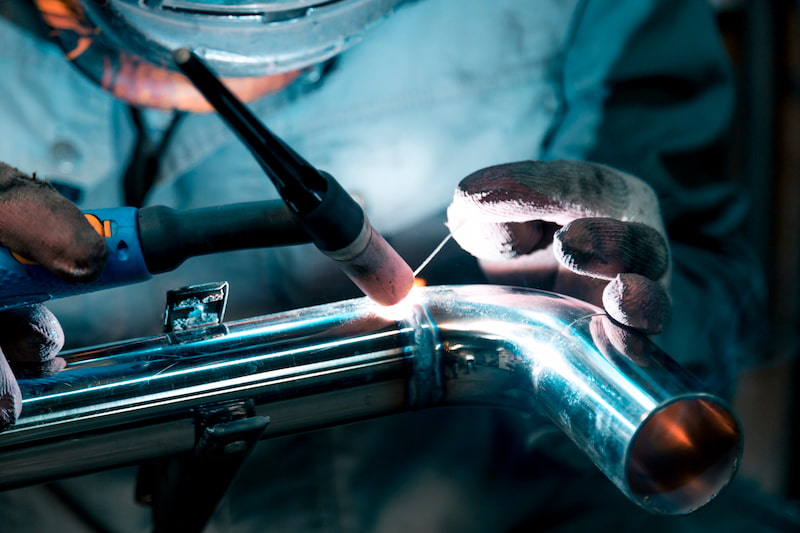

TIG welding is widely used in various industries, including aerospace, automotive, and medical. In the aerospace industry, TIG welding is used to join thin sheets of metal and create complex shapes. In the automotive industry, TIG welding is used to create exhaust systems and repair body panels. In the medical industry, TIG welding is used to create medical devices and implants.

Example

For example, in the aerospace industry, TIG welding is used to join aluminum alloys, which are lightweight and strong. TIG welding allows for precise control of the heat, making it ideal for welding thin sheets of metal.

Conclusion

In conclusion, TIG welding is a popular welding process used in various industries. The process involves using a tungsten electrode to heat the metal and an inert gas to protect the weld. TIG welding offers several advantages, including precision, cleanliness, and versatility, but also has some disadvantages, including being time-consuming and requiring a high skill level.

In summary, TIG welding is a precise and clean welding process used in various industries, including aerospace, automotive, and medical. The process involves several steps, including preparation, tack welding, welding, and finishing. While TIG welding offers several advantages, it also has some disadvantages and requires a high level of skill and experience.