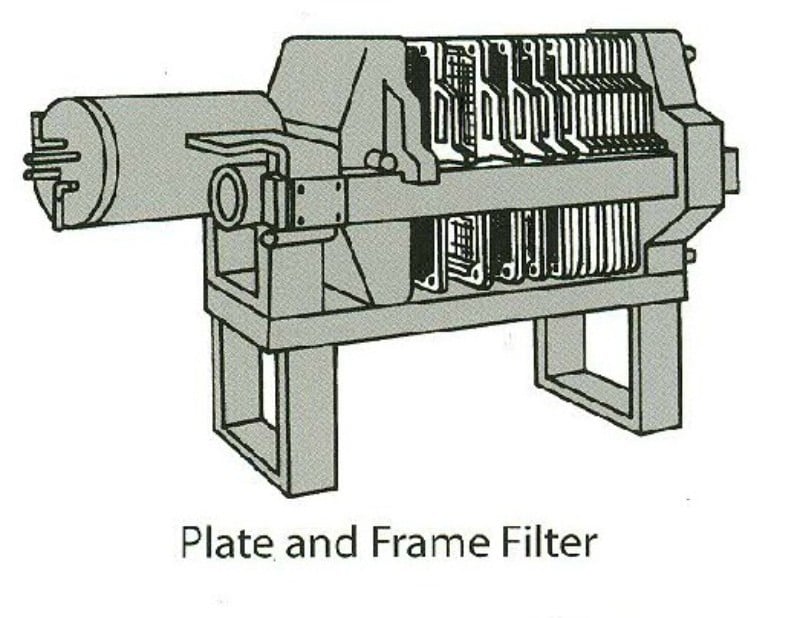

Plate and frame filter press is a widely used filtration equipment in various industries, including chemical, pharmaceutical, food, and beverage. It works on the principle of separating solids from liquids by passing the mixture through a series of filter plates and frames. This article will discuss the working principle of the plate and frame filter press, its applications, and some advantages and disadvantages.

Working Principle:

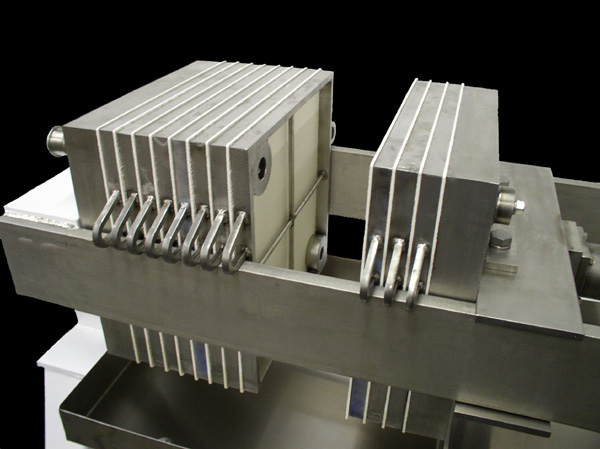

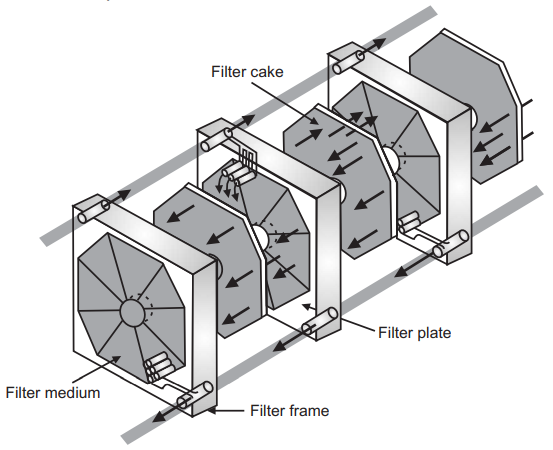

The plate and frame filter press consists of a series of filter plates and frames arranged alternately. The plates have a hollow frame and a flat surface, and the frames have a central opening for the filtrate to pass through. The mixture to be filtered is pumped into the press, and the solid particles are trapped between the plates, forming a filter cake. The liquid filtrate passes through the filter cloth and the central opening of each frame, collecting in a collection tray.

After the filtration process is complete, the filter cake is removed from the plates, and the press is ready for the next cycle. The filter plates and frames are usually made of plastic, metal, or ceramic materials, depending on the application.

Applications:

The plate and frame filter press is used in a wide range of applications, including:

- Chemical industry: Separation of catalysts, pigments, and other solids from liquids.

- Pharmaceutical industry: Purification of antibiotics, enzymes, and other active ingredients.

- Food and beverage industry: Clarification of fruit juices, beer, and wine.

- Mining industry: Dewatering of metal concentrates and tailings.

- Environmental industry: Treatment of wastewater and sludge.

Advantages:

The plate and frame filter press offers several advantages, including:

- High filtration efficiency: The filter plates and frames provide a large filtration area, resulting in high throughput and fast filtration.

- Easy to operate: The filtration process is automated, requiring minimal supervision and maintenance.

- Versatility: The filter press can handle a wide range of solids and liquids, making it suitable for various applications.

- Low cost: The initial investment and operating cost of the plate and frame filter press are relatively low, making it an affordable option for small and medium-sized enterprises.

Disadvantages:

Despite its advantages, the plate and frame filter press has some limitations, including:

- Low solids capture efficiency: The filter cloth may not capture all the solid particles, resulting in incomplete filtration.

- High cake moisture content: The filter cake may retain a significant amount of moisture, requiring additional drying steps.

- Long cycle time: The filtration cycle time may be longer than other filtration methods, resulting in lower productivity.

Conclusion:

The plate and frame filter press is a reliable and cost-effective filtration equipment that has been used in various industries for many years. Its working principle is simple yet effective, and it offers several advantages over other filtration methods. However, it also has some limitations that should be considered when selecting filtration equipment for a specific application.