A 4-inch gate valve is a crucial component in fluid control systems, offering efficient flow regulation and shut-off capabilities. Designed to handle moderate to high-pressure applications, this valve size is widely used in various industries. This article explores the features, benefits, and applications of 4-inch gate valves, highlighting their importance in fluid control systems.

Understanding the 4-Inch Gate Valve

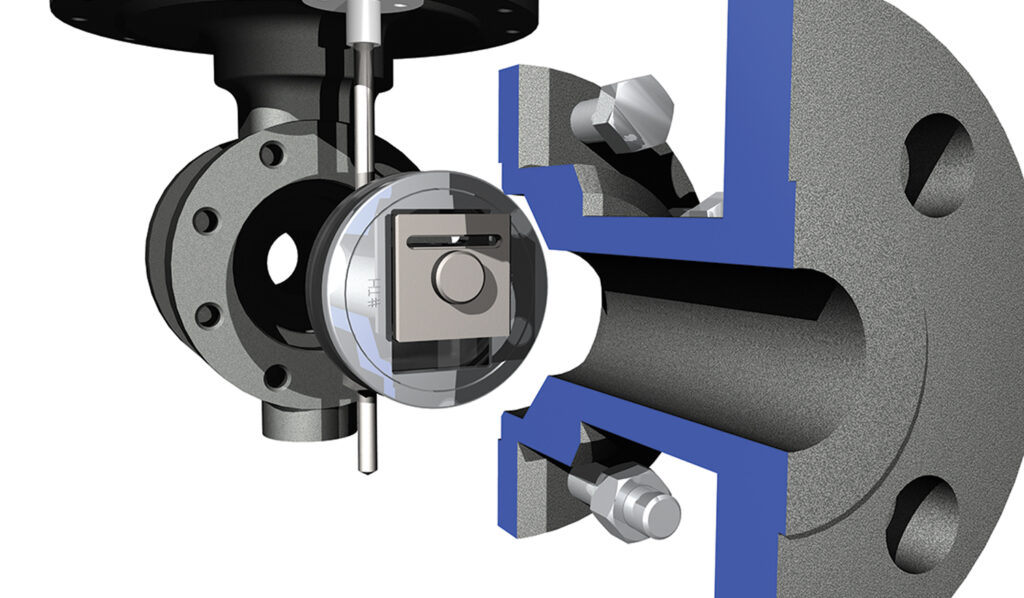

A 4 inch gate valve is a type of valve with a nominal diameter of four inches. It features a sliding gate mechanism that controls the flow of fluids through a pipe. The gate valve’s sturdy construction and reliable sealing mechanism make it ideal for managing the flow of liquids and gases in industrial settings.

Features and Benefits of 4-Inch Gate Valves

- Robust Construction:

4-inch gate valves are built to withstand high-pressure environments. They are typically constructed from durable materials such as stainless steel, cast iron, or bronze, ensuring long-lasting performance and resistance to corrosion. - Efficient Flow Control:

The sliding gate mechanism of a 4-inch gate valve allows for precise flow regulation. By raising or lowering the gate, operators can control the fluid’s rate and direction, providing efficient flow control and minimizing pressure drops. - Reliable Shut-off Capability:

4-inch gate valves offer a tight shut-off, preventing the passage of fluids when fully closed. This feature is crucial in applications where complete isolation is required, ensuring safety and preventing leaks. - Versatile Applications:

4-inch gate valves find applications in various industries, including oil and gas, water treatment, chemical processing, and power generation. They are commonly used in pipelines, refineries, process plants, and distribution systems for fluid control and isolation.

Applications of 4-Inch Gate Valves

- Oil and Gas Industry:

4-inch gate valves are widely employed in the oil and gas sector for controlling the flow of crude oil, natural gas, and refined products. They are essential components in pipelines, storage tanks, and offshore platforms, ensuring safe and efficient operations. - Water Treatment Facilities:

In water treatment plants, 4-inch gate valves are used to control the flow of water during treatment processes. These valves allow operators to regulate the water supply, isolate sections of the system for maintenance, and prevent backflow. - Chemical Processing Plants:

4-inch gate valves play a crucial role in chemical processing plants, where they control the flow of various chemicals, acids, and solvents. Their reliable shut-off capability and resistance to corrosive substances make them an ideal choice for these applications. - Power Generation:

In power plants, 4-inch gate valves are utilized to manage the flow of steam, condensate, and cooling water. They are vital components in boilers, turbines, and heat exchangers, ensuring efficient energy generation and system operation.

Conclusion:

A 4-inch gate valve is a versatile and reliable component in fluid control systems across various industries. With their robust construction, efficient flow control, and reliable shut-off capability, these valves provide optimal performance and enhance operational efficiency. From the oil and gas industry to water treatment facilities and chemical processing plants, 4-inch gate valves play a vital role in managing fluid flow and ensuring system integrity. Embrace the benefits of 4-inch gate valves and experience enhanced fluid control in your industry.