Grooved couplings and fittings are an essential part of many industrial applications, including plumbing, HVAC, and automotive systems.In this article, we will provide a comprehensive guide to grooved couplings and fittings, including their definition, types, and applications.

Definition of Grooved Couplings and Fittings

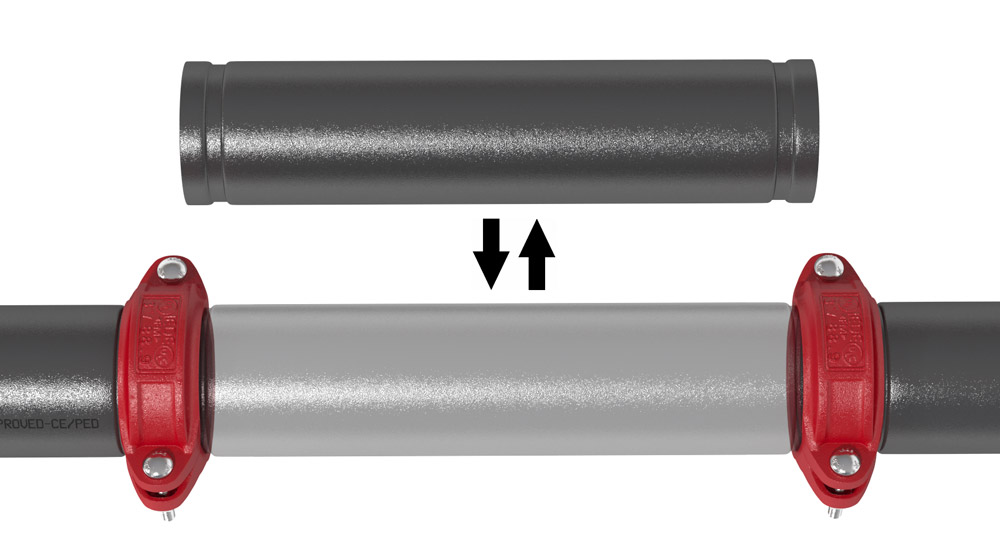

Grooved couplings and fittings are designed to connect pipes and tubes with a grooved end. The groove is a spiral-shaped channel that runs along the length of the pipe or tube and is used to receive the coupling or fitting. The coupling or fitting is designed to fit snugly into the groove, creating a secure and leak-free connection.

Types of Grooved Couplings and Fittings

There are several types of grooved couplings and fittings available, including:

Grooved Couplings: These are used to connect two pipes or tubes with a grooved end. They are available in various sizes and materials, including stainless steel, carbon steel, and copper.

Grooved Fittings: These are used to connect a pipe or tube with a grooved end to a fitting, such as an elbow, tee, or coupling. They are available in various sizes and materials, including stainless steel, carbon steel, and copper.

Grooved Adapters: These are used to connect a pipe or tube with a grooved end to a fitting or coupling that has a different type of connection, such as a threaded or welded connection.

Grooved Unions: These are used to connect two pipes or tubes with a grooved end, and allow for easy disconnection and reassembly.

Applications of Grooved Couplings and Fittings

Grooved couplings and fittings are used in a wide range of industrial applications, including:

Plumbing: Grooved couplings and fittings are used to connect pipes and tubes in plumbing systems, including water supply, drainage, and gas systems.

HVAC: Grooved couplings and fittings are used to connect pipes and tubes in heating, ventilation, and air conditioning systems.

Automotive: Grooved couplings and fittings are used to connect pipes and tubes in automotive systems, including brake lines, fuel lines, and cooling systems.

Chemical Processing: Grooved couplings and fittings are used to connect pipes and tubes in chemical processing systems, including those used for chemical production, refining, and transportation.

Advantages of Grooved Couplings and Fittings

Grooved couplings and fittings offer several advantages, including:

Leak-free connection: Grooved couplings and fittings provide a secure and leak-free connection, ensuring that fluids and gases are transmitted safely and efficiently.

Easy installation: Grooved couplings and fittings are easy to install, and do not require specialized tools or expertise.

Versatility: Grooved couplings and fittings are available in a wide range of sizes and materials, making them suitable for a variety of applications.

Cost-effective: Grooved couplings and fittings are cost-effective, as they do not require additional components, such as gaskets or O-rings, to create a seal.

Conclusion

Grooved couplings and fittings are an essential part of many industrial applications, providing a secure and leak-free connection between pipes and tubes. They are available in various sizes and materials and offer several advantages, including ease of installation, versatility, and cost-effectiveness.

By understanding the definition, types, and applications of grooved couplings and fittings, industries can make informed decisions when selecting the right coupling or fitting for their specific needs.