Miniature peristaltic pumps differ from standard-sized peristaltic pumps primarily in their size, flow rates, and application versatility. Here are some key differences:

- Size and Form Factor: Miniature peristaltic pumps are significantly smaller and more compact than standard-sized pumps. They are designed to occupy minimal space and often feature lightweight, portable designs, making them suitable for applications where space is limited or mobility is required.

- Flow Rates: Miniature peristaltic pumps typically have lower flow rates compared to standard-sized pumps. While standard pumps may be capable of delivering higher volumes of fluid per minute, miniature pumps are optimized for precision dispensing or microfluidic applications that require lower flow rates and finer control over fluid delivery.

- Fluid Handling Capabilities: Standard-sized peristaltic pumps are generally capable of handling a wider range of fluid viscosities, pressures, and temperatures compared to miniature pumps. Miniature pumps may have limitations in terms of the viscosity or pressure of the fluids they can effectively pump, although they are often suitable for handling a variety of fluids in laboratory, medical, and analytical applications.

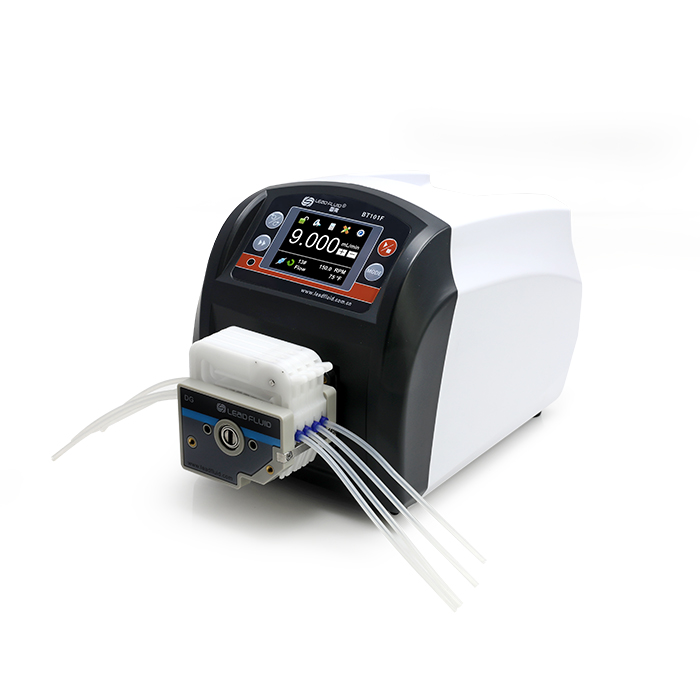

- Precision and Accuracy: Miniature peristaltic pumps are engineered for precise fluid delivery and dispensing applications, where accuracy and repeatability are critical. They often feature advanced control mechanisms, miniature peristaltic pump such as stepper motors or servo drives, to achieve precise flow rates and volume control, whereas standard pumps may offer less precise control over fluid delivery.

- Application Specificity: Miniature peristaltic pumps are commonly used in specialized applications such as analytical chemistry, laboratory automation, medical devices, and microfluidics, where compact size, precise fluid handling, and portability are essential. Standard-sized pumps, on the other hand, are employed in a wider range of industrial, environmental, and process applications that require higher flow rates and robust fluid handling capabilities.

- Cost: Due to their smaller size and specialized design, miniature peristaltic pumps may be more expensive on a per-unit basis compared to standard-sized pumps. However, their suitability for precision applications and compact form factor often justifies the higher cost for applications where accuracy and space constraints are paramount.

Overall, while miniature peristaltic pumps share the fundamental operating principle of standard-sized pumps—utilizing a rotating roller or rotor to compress a flexible tubing— they are optimized for different applications that prioritize compact size, precision fluid handling, and portability over high flow rates and robust fluid handling capabilities.