Discover the versatility and reliability of galvanized grooved fittings for plumbing and fire protection systems. This comprehensive guide explores the features and benefits of using galvanized grooved fittings, including their corrosion resistance and durability.

Understanding the Features and Benefits of Galvanized Grooved Fittings

Galvanized grooved fittings offer a reliable and efficient way to connect pipes in plumbing and fire protection systems. Made from galvanized steel, these fittings provide excellent corrosion resistance and durability.

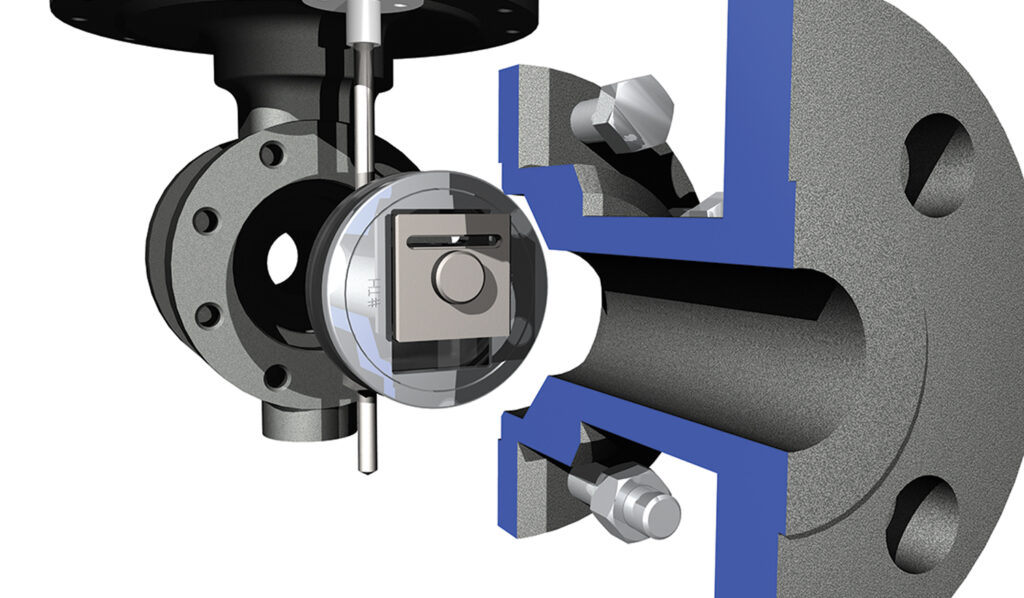

The benefits of using galvanized grooved fittings include their ease of installation, compatibility with various pipe materials, and the ability to withstand high pressure and temperature conditions.

Applications of Galvanized Grooved Fittings in Plumbing Systems

In plumbing systems, galvanized grooved fittings are widely used for connecting pipes in residential, commercial, and industrial buildings.

These fittings ensure secure and leak-resistant connections for water supply, drainage, and HVAC systems. They are particularly suitable for applications that require efficient water flow and reliable connections.

Applications of Galvanized Grooved Fittings in Fire Protection Systems

Galvanized grooved fittings play a crucial role in fire protection systems, including sprinkler installations. These fittings provide secure connections that can withstand high pressure and temperature conditions.

They ensure the effectiveness of fire suppression systems by enabling the proper flow of water to extinguish fires and protect lives and property.

Considerations for Working with Galvanized Grooved Fittings:

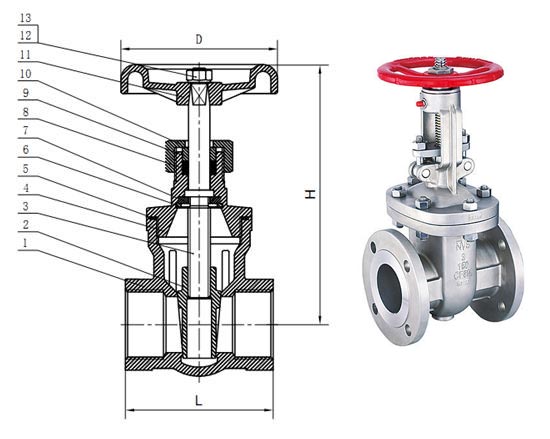

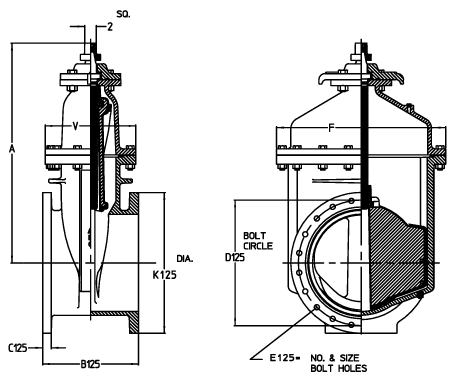

Proper Pipe Preparation: Before installation, it is essential to properly prepare the pipes by removing burrs, debris, and ensuring clean and smooth pipe ends. This ensures accurate and secure connections with galvanized grooved fittings.

Correct Installation Techniques:

Follow the manufacturer’s instructions for the correct installation of galvanized grooved fittings. Use the appropriate tools, apply the proper torque, and inspect the fittings for proper alignment and engagement.

Example Applications:

In plumbing systems, galvanized grooved fittings are commonly used to connect pipes for water distribution in commercial buildings. These fittings provide secure and leak-resistant connections, ensuring efficient water flow throughout the building.

Similarly, in fire protection systems, galvanized grooved fittings are utilized to connect pipes for sprinkler installations. The reliable connections offered by these fittings help ensure the effectiveness of fire suppression systems in case of emergencies.

Conclusion:

Galvanized grooved fittings offer versatile and reliable connections for plumbing and fire protection systems. Their corrosion resistance, durability, and ease of installation make them an ideal choice for various applications.

By considering proper pipe preparation and correct installation techniques, you can effectively utilize galvanized grooved fittings for secure and efficient connections. Maximize the potential of these fittings to ensure the success of your plumbing and fire protection projects.