Mechanical pipe fittings are an essential part of any piping system, providing a vital connection between pipes and allowing for the efficient transfer of fluids, gases, and slurries.

Mechanical pipe fittings are designed to withstand high pressures and temperatures, making them ideal for use in a wide range of industries.

From oil and gas to chemical processing and water treatment. In this article, we will explore the features of mechanical pipe fittings and their various uses.

Types of Mechanical Pipe Fittings

There are several types of mechanical pipe fittings available, each with its unique features and applications. Some of the most common types include:

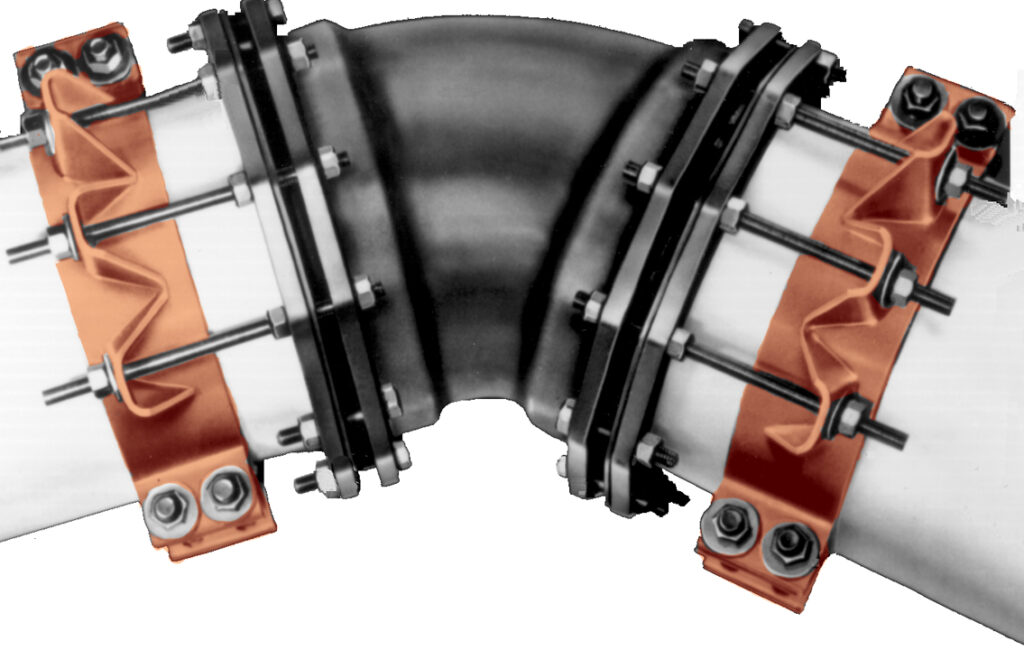

- Elbows: These fittings are used to change the direction of a pipe by 90 degrees or 180 degrees. They are commonly used in tight spaces where a regular bend would be difficult to install.

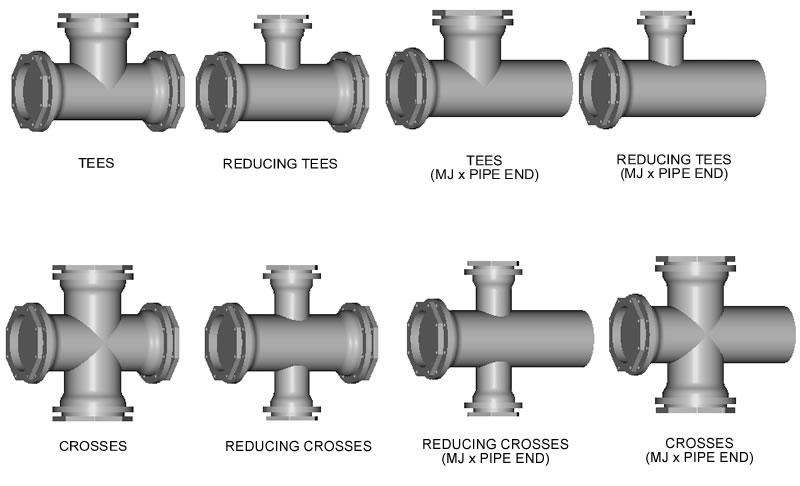

- Tees: Tees are used to connect three pipes, creating a T-shaped junction. They are commonly used in hydraulic systems, chemical plants, and oil refineries.

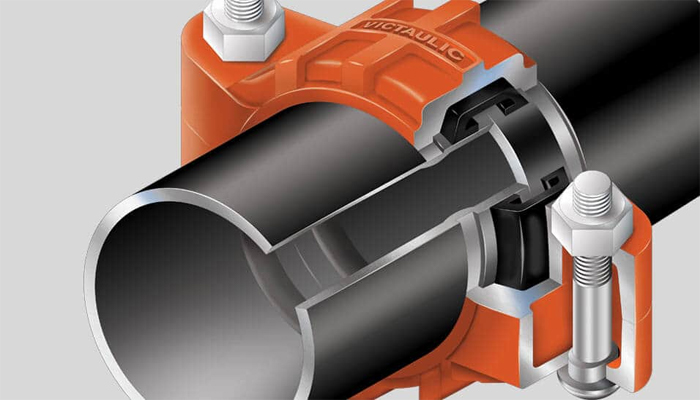

- Couplings: Couplings are used to connect two pipes, creating a secure and leak-tight joint. They are commonly used in water distribution systems, gas lines, and sewage systems.

- Unions: Unions are similar to couplings, but they allow for the easy disconnection of pipes. They are commonly used in maintenance and repair applications.

- Plugs: Plugs are used to block off the end of a pipe, preventing fluid from flowing through it. They are commonly used in oil and gas production, chemical processing, and water treatment.

- Bushings: Bushings are used to reduce the size of a pipe, allowing for the connection of pipes with different diameters. They are commonly used in oil and gas production, chemical processing, and water treatment.

Applications of Mechanical Pipe Fittings

Mechanical pipe fittings have a wide range of applications across various industries, including:

- Oil and Gas Production: Mechanical pipe fittings are used extensively in oil and gas production, particularly in offshore drilling and refining. They are used to connect pipes in production platforms, refineries, and transportation systems.

- Chemical Processing: Chemical processing plants use mechanical pipe fittings to connect pipes carrying corrosive and abrasive chemicals. They are also used in reaction vessels, heat exchangers, and storage tanks.

- Water Treatment: Mechanical pipe fittings are used in water treatment plants to connect pipes carrying raw water, treated water, and sludge. They are also used in filtration systems, pumping stations, and distribution systems.

- HVAC Systems: Mechanical pipe fittings are used in heating, ventilation, and air conditioning (HVAC) systems to connect pipes carrying water, steam, and refrigerant. They are also used in ductwork and air-handling units.

- Marine Applications: Mechanical pipe fittings are used in marine applications, such as in ships and offshore platforms, to connect pipes carrying fuel, water, and other fluids.

Benefits of Mechanical Pipe Fittings

Mechanical pipe fittings offer several benefits, including:

- Durability: Mechanical pipe fittings are designed to withstand high pressures and temperatures, making them ideal for use in harsh environments.

- Versatility: Mechanical pipe fittings are available in a range of materials, including carbon steel, stainless steel, and bronze, allowing them to be used in a variety of applications.

- Easy Installation: Mechanical pipe fittings are easy to install, requiring minimal welding and cutting.

- Cost-Effective: Mechanical pipe fittings are cost-effective, reducing the need for expensive welding and cutting equipment.

Conclusion

Mechanical pipe fittings are an essential part of any piping system, providing a vital connection between pipes and allowing for the efficient transfer of fluids, gases, and slurries. They are available in a range of materials and types, each with its unique features and applications.